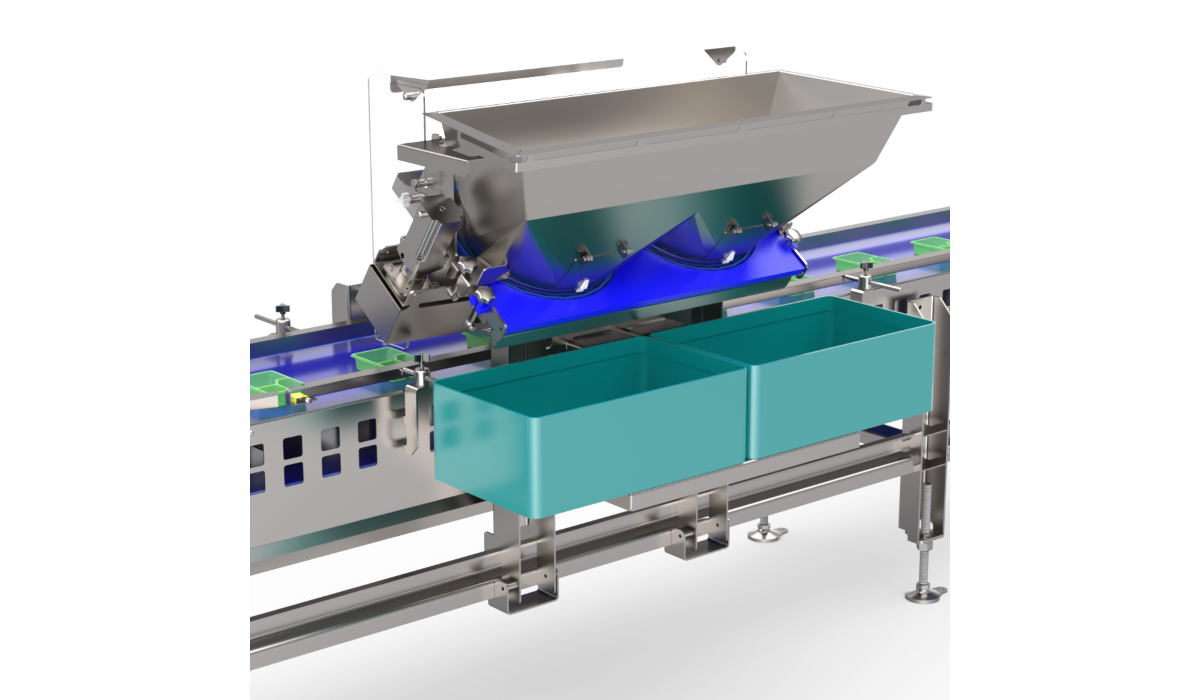

GENERAL DESCRIPTION:

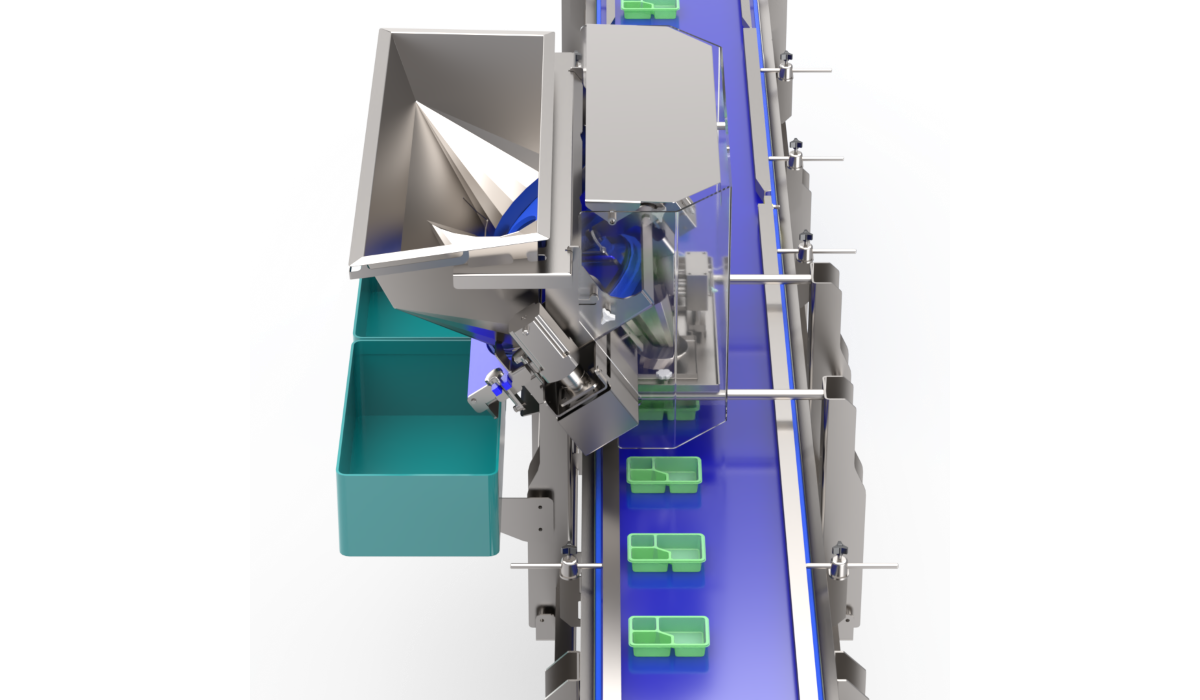

Angular Dial Fillers are used to fill a predetermined (target weight) amount of an ingredient measured by volume rather than weight. Our Angular Dial Fillers have multiple pocket sizes available depending on the ingredients being dispensed. Our ADF’s eliminate product give-away caused by manual filling and give you the correct amount of product every time. Using these ADF’s reduce the amount of headcount and skilled labor on the production lines. Machines can be customized depending on your specific requirements.

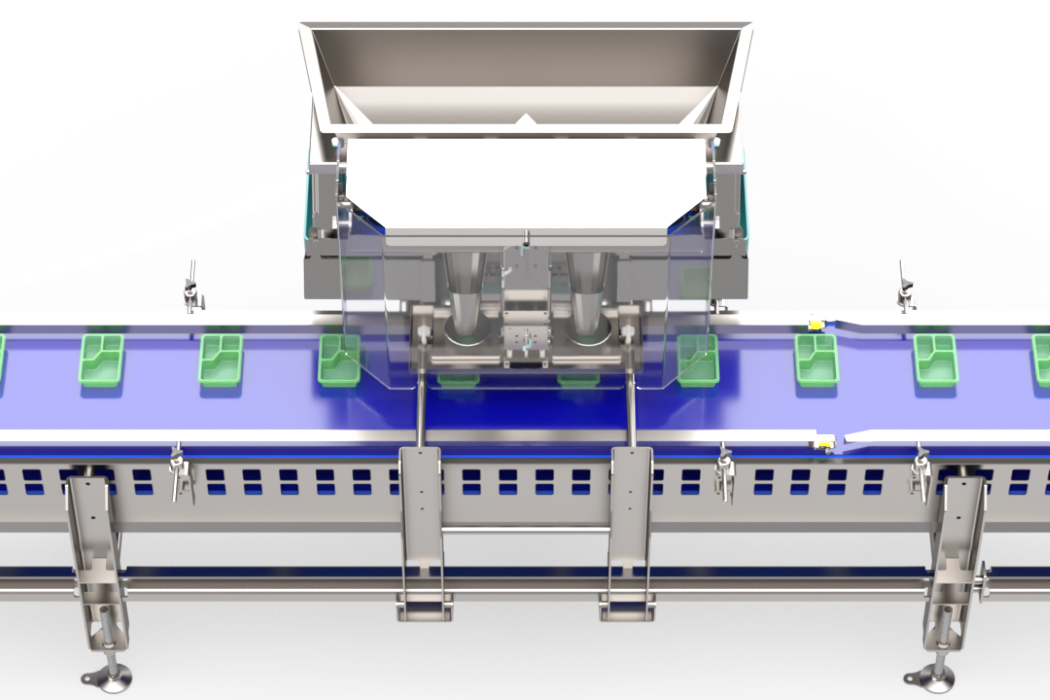

The Operation of the filler begins with the bulk product being dumped into the hopper and rotary volumetric disc. The disk rotates under the bulk product filling the pockets, there, product guides and wipers ensure the product pockets are full while indexing to the fill position where the product then drops to two containers at once. Machines can be ordered with a tooling /sanitation cart for easy access to changeover parts and easy sanitation of stored parts.

DESIGN FEATURES:

• Dual Container FIll Per Index

• Tracking Feature -No Container / No Fill-

• Sanitary Friendly Open Frame Design

• All Support Structure and Food Contact Surfaces Fabricated with AISI304 Stainless Steel

• All Nuts & Bolts are 18-8 Stainless Steel Unless Otherwise Specified.

• All Servo Motors and Cabling are IP65 Certified or Better.

• All Plastic is Food Grade and USDA Approved.

• Watershed Enclosure.