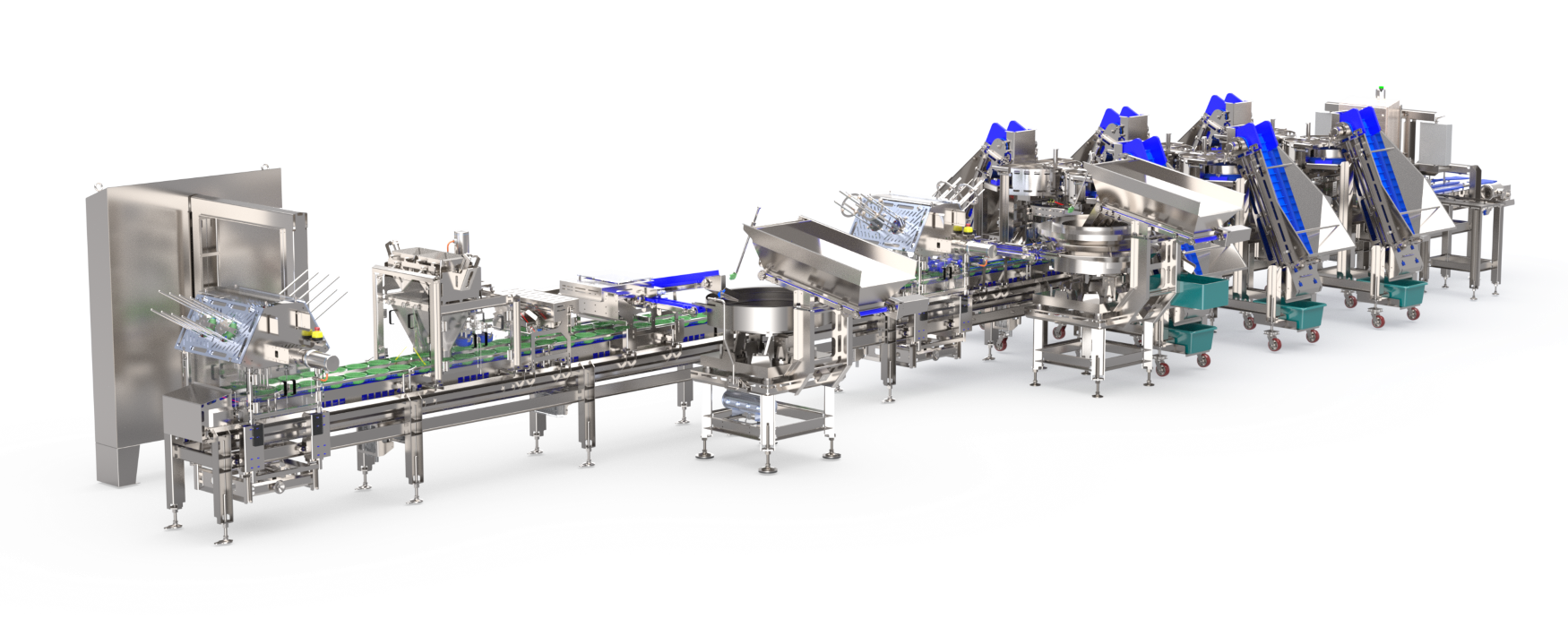

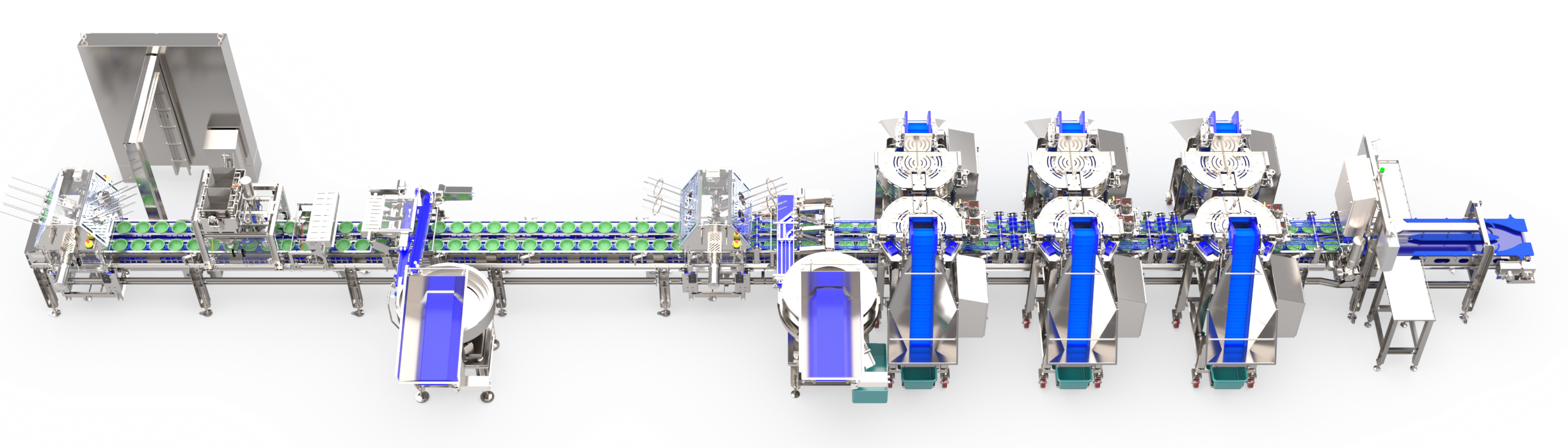

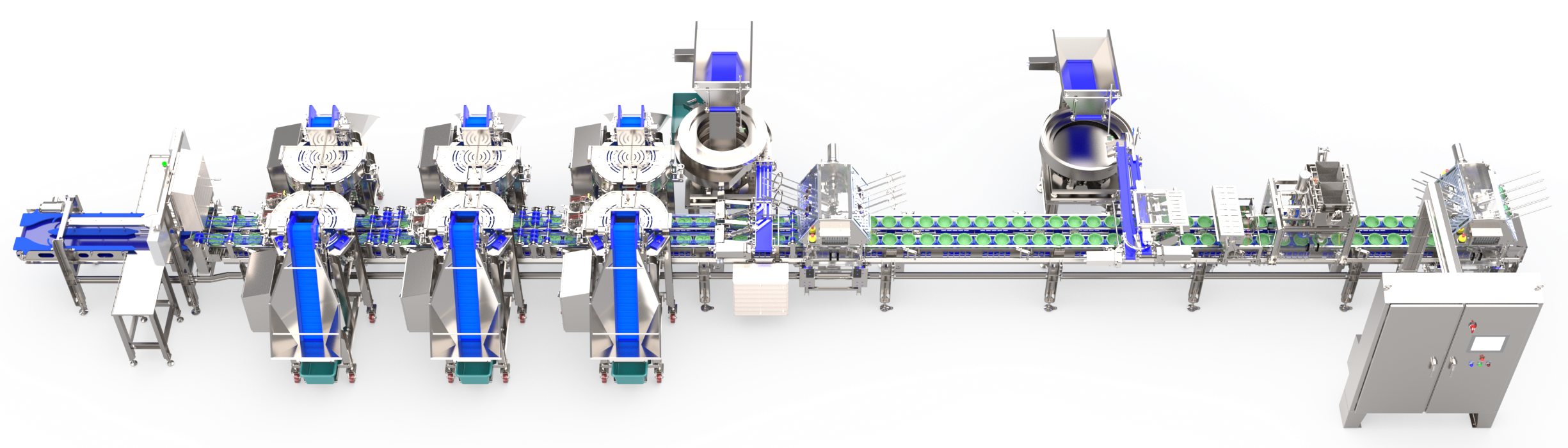

GENERAL DESCRIPTION:

Our most complete Bowl Filling Systems yet, these Filling Systems are primarily used for filling ridged containers (Ready To Eat) and perform a series of functions in synchronicity to reduce cycle times and produce a nicely filled container for your end users. Our inline filling systems are the most efficient systems on the market today, we take the base product drop from a scale stack and place it automatically into the bowl, from here, we complete the bowl/tray assembly incorporating either automated or manual placers for condiments and eating utensils into our systems. These systems are versatile enough for a quick changeover of tooling and ingredients for the varied sizes and recipes of containers you are wanting to fill. With the use of our new Rotatory Volumetric Fillers, we can fill the condiment tray with the proper ingredient amount every time on each receptacle.

We manufacture many different models and filling configurations to fit your needs and/or capacities. The amount of headcount and skilled labor needed with this process has been reduced with the use of our semi-automated systems. Our customers have seen an immediate reduction in cost per unit and a quick return on their investment.

DESIGN FEATURES:

• Sanitary friendly open frame design.

• All Support Structure and Food Contact Surfaces fabricated with AISI304 Stainless Steel.

• All nuts & bolts are 18-8 stainless steel unless otherwise specified.

• All Plastic is food grade and USDA approved.

• All gears, motors, and cabling are IP65 certified or better.

• Adjustable Height Secondary Tamper with Easy Change Tamper Design.

• Auto Bowl/Tray Denesting.

• Auto Condiment Tray / Lid Placing.

• Upgraded PanelView Screen.

• AB Compact Logix / Kinetix Platform.

• Tracking Feature on Container Filling and Product Placement.

• Watershed Enclosure.